#Acan laser engraving software

If you are not sure about the software you need – do not hesitate and ask us directly: Ī few things that you need to keep in mind: 1. Get all engraving/cutting software programs in one place. Explore STL files, installation programs, plugin extensions, and many other useful things.

#Acan laser engraving download

I've tried engraving plastic - specifically a PLA 3D print - the beam at 100% power burned right through the PLA like a hot knife through butter.For your convenience, you can find everything you need in our download center to have the best experience while working with Endurance lasers and engraving machines.Īll files here are free of charge and has no hidden ads or required registration. These turn out fantastic - the laser burns through the black and onto the metal surface beneath, and it results in a plaque that looks like it's been printed/dye-sub - very impressed, especially when set to a higher DPI > 500.

I also engrave black trophy plates which are aluminium coated in black (I think it may be an anodised coating). but it's still readable and adequate for what I need. They leave a darker mark (compared with the colour of the metal) where a normal engraver would mark out a much lighter etching. The trophy plaques are, I believe, aluminium (or brass), and available in silver or gold colour - again, the 15W laser engraves them very well. I engraved the back of my partners watch :) This 15W laser though (I'm not sure on the wavelength), is quite capable of marking steel. The reason for choosing this particular product: I was tempted with a 40w CO2 laser but even after reading some reviews, it suggested their wavelength couldn't cope with metal engraving. I'll defintely give DXF a go when I get home later today. Anything higher than that and you'll be reducing the life of your tube even faster. A better way is to find your power curve by measuring current consumption of the tube at various power levels, and stick with a maximum power % where the current draw does not exceed 20-30mA. In fact, it's usually the opposite for these Chinese tubes. I've never heard of always running the tube at 100%.

Otherwise you can try Cermark, but I suspect you won't have good results, even with exceptionally slow runs and high power.

If you're attempting to do metal, you're better off powedercoating/anodizing it and then using the laser to remove the paint. What material are you planning to engrave with a 15W laser? If it's anything other than wood or plastic, you're not going to be very successful. And yeah, if you want better software, you'll most likely have to swap the controller, which isn't going to be cheap (just had to purchase a replacement Ruida controller for our 80W and it was $300). Never worked with ACAN, but try converting your SVG to a DXF and importing that into the software.

#Acan laser engraving manual

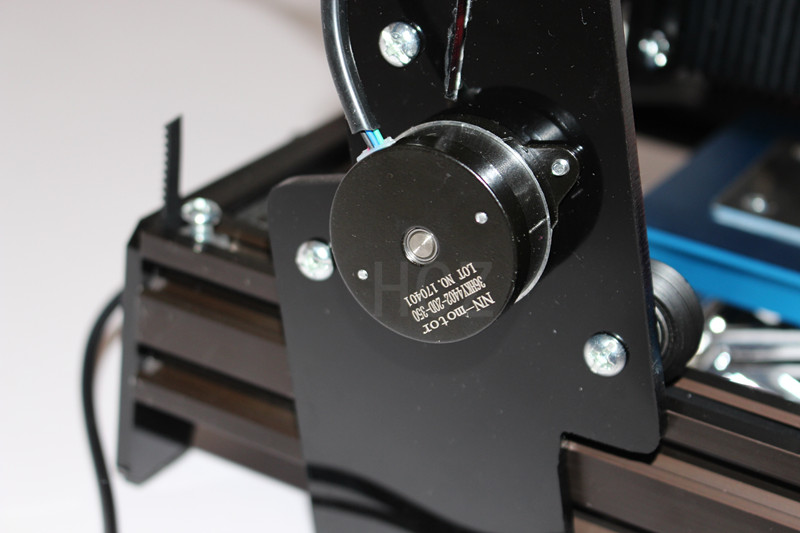

I read in the manual that reducing the power from anything other than 100% actually has a detrimental effect on the life of the laser module - is this correct? And if so, why? I had to reduce the laser power from 100% down to about 10% (and even then the marks were a bit too deep and brown). Secondly, 15W is sometimes a bit overkill for other applications - for example, I recently burned my girlfriends face onto the back of a wooden spoon for no particular reason other than I could. firstly, to anyone who has used this ACAN software - how can I engrave from SVGs? Apparently they're supported but I can't seem to open any of my SVG files, having instead to convert to raster/jpg before engraving, and subsequently increasing the engraving time for pixel based envgraving as opposed to vector. It seems I'm stuck with this ACAN software for now, at least until I swap out the control board for something more appropriate anyway. I have an idea that the control board on these Chinese assemblies is proprietory and so I can't use open sourse laser cutting software (I've come across GRBL which seems like it could be good?). My bug-bear however, is the software - it's terrible!! (it's ACAN for anyone who knows what it is). I come from a 3D printing background so have more than a basic knowledge of how these work, along with understanding of Gcode etc. The engraver did not cost a fortune, it was approx £400 and includes a small X-Y assembly and the important piece being the 15W laser module.

I bought it with the sole intention of engraving trophy plates - something I normally outsource to a 3rd party who engraves using a normal metal CNC/trophy engraver but as they've recently increased their prices and delivery times, I decided to bring it in house. I've recently bought a Chinese 15W laser engraver (not a cutter). I was going to post this in r/Laserengraving but this sub is a bit busier so I'll throw it here - feel free to remove it if it's not in the right place.

0 kommentar(er)

0 kommentar(er)